Salestech is proud to be the exclusive Australian dealer for Atemag

CNC aggregates. If you are looking to increase your machines output

consider what is possible with Atemag.

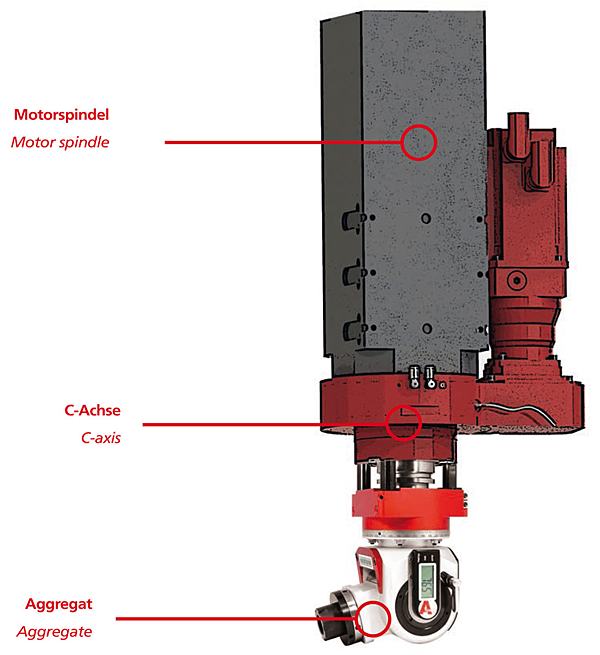

WHAT IS AN AGGREGATE?

ATEMAG products support the functionality of CNC machines.

The tool output, which is vertically fixed by the motor spindle at 0 °, can be transferred to a different axis or to any angle. The standard is a 90 ° unit (MONO, DUO, QUATTRO) to process horizontal drilling, routing, or sawing deppending on the Outputs selected.

Even with a 5-axis machine equipped with a swivel motor spindle, ATEMAG units are used. These allows the scanning / copying of the workpiece surface to ensure a 100% machining result despite material fluctuations.

ATEMAG has specialized since its inception in the development and distribution of aggregates. This know – how, combined with the use of high - quality components, and the philosophy of ATEMAG contribute to that development.

ATEMAG units are designed for continuous use

ATEMAG aggregates are not produced by an assembly line. Each aggregate hand assembled by one mechanic who takes notes of every single step. The aggregates are individual items and are identified by a serial number. This makes it possible to track information on each aggreggate even years later. We place great value on partners from the region out of the quality reason.

Continuous development means that even standard units, which have been in the program for years, are always technically up-to-date. This includes high process reliability (e.g. in oil bath lubrication techniques).

All this is ensured by the house development and construction team. This means that each unit can be adapted and offered for each machine

The tool output, which is vertically fixed by the motor spindle at 0 °, can be transferred to a different axis or to any angle. The standard is a 90 ° unit (MONO, DUO, QUATTRO) to process horizontal drilling, routing, or sawing deppending on the Outputs selected.

Even with a 5-axis machine equipped with a swivel motor spindle, ATEMAG units are used. These allows the scanning / copying of the workpiece surface to ensure a 100% machining result despite material fluctuations.

ATEMAG has specialized since its inception in the development and distribution of aggregates. This know – how, combined with the use of high - quality components, and the philosophy of ATEMAG contribute to that development.

ATEMAG units are designed for continuous use

ATEMAG aggregates are not produced by an assembly line. Each aggregate hand assembled by one mechanic who takes notes of every single step. The aggregates are individual items and are identified by a serial number. This makes it possible to track information on each aggreggate even years later. We place great value on partners from the region out of the quality reason.

Continuous development means that even standard units, which have been in the program for years, are always technically up-to-date. This includes high process reliability (e.g. in oil bath lubrication techniques).

All this is ensured by the house development and construction team. This means that each unit can be adapted and offered for each machine

Modular

Grease or Oil

Grease lubrication with high performance grease for high speed.

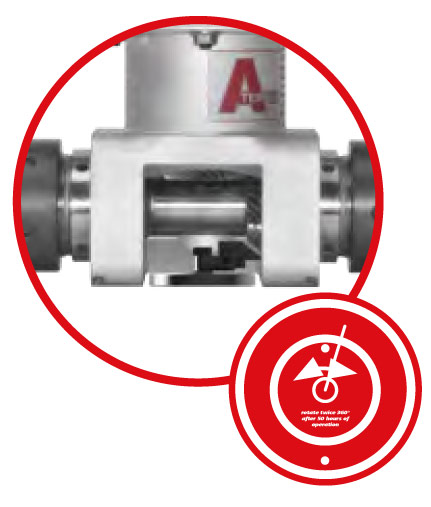

Manual, easy and effective. You will find the Rota Lube System in all ATEMAG MONO, DUO, EXTRA and QUATTRO aggregates.

Automatic lubrication cartridge used with multi spindle heads for optimum lubrication.

Oil lubrication for high torque, heavy duty and sawing operations.